UV Stabilised Cable Ties: The No-Nonsense Guide for Outdoor Jobs

UV Stabilised Cable Ties: The No-Nonsense Guide for Outdoor Jobs

If you've ever run cables outdoors or worked on sites in direct sunlight, (such as solar farms) you’ll know regular cable ties only have a life expectancy of one to two years. They become brittle, snap, or just disintegrate over time. That’s because the sun’s UV rays break down the chemical components of the nylon that the humble cable tie is made from. The heat from the sun also dries out the nylon. Then on top of this the weather eats away at the plastic. This is where UV stabilised cable ties make all the difference.

I’ve been in the cable tie business for over 30 years and seen what works, what doesn’t, and how a job can go wrong if you cut corners on materials. In this guide, I’ll explain what UV stabilised cable ties are, why they matter, and how to choose the right ones for proper outdoor work.

What Are UV Stabilised Cable Ties?

These are not your everyday ties. UV stabilised cable ties are made to handle long-term exposure to sun and weather. They’re designed with extra carbon and stabilisers built into the plastic, which protects them from UV rays that normally break down standard ties.

Standard cable ties usually have around 1% carbon. That’s not enough. UV-rated ties have at least 2% carbon plus UV-stabilising additives, which makes them stronger and longer-lasting in sunlight.

Why Normal Cable Ties Fail in the Sun

UV rays have a high-energy radiation that breaks down the structure within the cable tie. This is called photodegradation, and you can see signs of it in the following ways:

-

Colour fading: The tie's original colour begins to fade as the structure changes

-

Material brittleness: The nylon becomes increasingly fragile and prone to cracking

-

Reduced tensile strength: The tie's holding power greatly reduces

-

Surface chalking: A powdery residue appears on the surface as the material degrades

If your cable ties are securing power lines, solar panel wiring, scaffold netting, or irrigation systems, failure isn’t just annoying — it’s dangerous or costly to fix.

The Key Benefits of Proper UV Cable Ties

✅ Higher Carbon Content & Stabilisers

UV stabilised cable ties contain a combination of 2% carbon content and stabilisers. This design reduces the damage caused by UV radiation far more than the 1% carbon found in a standard cable tie.

✅ Wide Temperature Range

UV cable ties can handle -40°C to +120°C. Whether you're working in freezing winds or direct summer sun on a rooftop, they stay strong.

✅ Flame Rating

Look for ties rated UL 94 V-2 — this means they won’t easily catch or spread flame, which matters in electrical or industrial jobs.

✅ Lifespan

UV cable ties have a life expectancy 5 to 10 times longer than standard ties. These types of cable ties should last between 5 and 10 years.

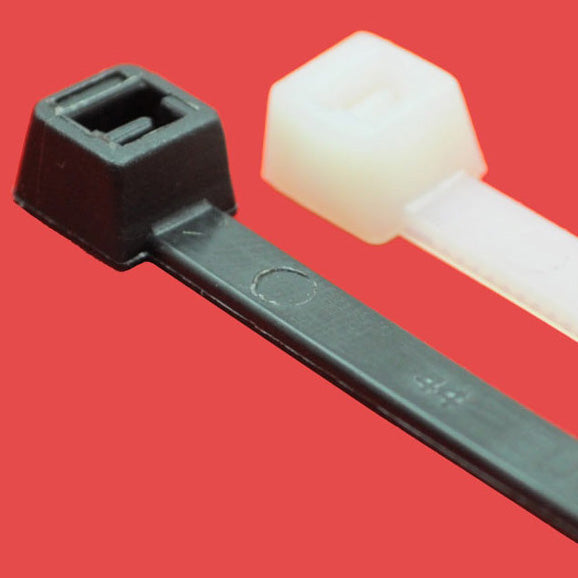

Black vs White (Which Should You Use?)

Black UV cable ties are the most common for outdoor use. They offer the best protection and blend in well with most installations. These ties usually last 5 to 10 years outdoors.

White UV ties (which have a slightly green tint) are also available, but they generally have a slightly shorter lifespan. These are good if you need visibility or want the tie to stand out.

Just a heads-up: not all black ties are UV stabilised. Colour alone doesn’t guarantee UV protection, so make sure you check the technical specs.

Where Are UV Stabilised Cable Ties Commonly Used?

🔌 Electrical & Telecoms

Whether you have long cable runs, are securing cables to junction boxes, or installing equipment, these ties stay in place, don’t crack, and don’t need replacing after a year.

☀️ Solar Panel Installations

Solar and other renewable energy sources have a real need for UV stabilised cable ties for securing wiring harnesses and mounting components. These systems are designed to operate for 20+ years in direct sunlight, so using anything less than a UV stabilised cable tie would be potentially dangerous and costly.

🏭 Industrial & Manufacturing

Manufacturing plants, chemical processing facilities, and other industrial environments often require cable ties that can withstand both UV exposure and high temperatures. UV stabilised and heat-resistant cable ties provide the necessary durability for these demanding conditions.

🌱 Agriculture & Horticulture

UV stabilised cable ties are used to secure irrigation systems, tie plants to growth structures, and organise equipment in greenhouses. The combination of UV resistance and chemical stability makes them perfect for these uses.

🌊 Coastal & Marine Areas

Coastal environments offer a unique challenge — the combination of salty sea air, intense sunlight, and fluctuating temperatures means that it is crucial to have a cable tie that is UV resistant and heat stabilised. This makes these cable ties ideal for boat installations and coastal infrastructure.

What to Consider Before Installation

📏 Size Selection:

Selecting the right size and tensile strength is vital for any cable tie use. UV stabilised cable ties are available in various sizes, from small 2.5mm wide ties for light-duty work (minimum tensile strength of 8kg) to 12.7mm wide for really heavy-duty applications (minimum tensile strength of 114kg). Similarly, the length of the tie is crucial for bundle diameter — with 100mm for small bundles (maximum diameter 22mm) to 1030mm long for large bundles (maximum bundle diameter 312mm). Make sure you choose the correct size cable tie for the job. We have a handy size chart you can use here.

🧰 Use Tension Tools When You Can

While you can install UV stabilised cable ties by hand, a professional installation can only benefit from using cable tie tensioning tools. These tools allow for a cleaner, more consistent, professional look, as well as reducing hand fatigue and increasing speed of application on large runs.

☀️ Think About Placement

Even UV stabilised ties degrade over time. However, proper installation practices can extend their lifespan. Where you can, think about the placement of the ties to ensure minimum exposure to intense direct sunlight. Also, ensure that there is enough drainage — standing water can increase the breakdown even in UV-resistant materials.

Common Misconceptions

“All black cable ties are UV-resistant.”

This is one of the most common misconceptions in the industry. While the black pigmentation does provide some UV protection, it is not enough for long-term outdoor use. Only cable ties that have been specifically manufactured with 2% carbon and enhanced stabilisers can truly be thought of as UV resistant. Always check the manufacturer’s specifications rather than just assuming that black cable ties mean UV resistant.

“UV ties are only for outdoor use.”

This statement is not true. While UV resistant cable ties are ideal for outdoor use, there are several indoor environments that benefit from the use of UV resistant and heat-stabilised cable ties. This includes laboratories that use UV sterilisation processes for their equipment, industries that use a UV curing process, and even some retail settings that use intense artificial light. These settings can all benefit from the use of UV resistant ties.

Is It Worth the Extra Cost?

Although UV stabilised cable ties usually cost more than standard cable ties, for long-term projects these ties will be far more cost-effective.

Things you need to consider when thinking about the price:

-

UV stabilised and heat-resistant cable ties will greatly reduce the need for replacement and maintenance. This is really valuable in areas that are difficult to access, where labour costs are high.

-

The increased durability of UV stabilised cable ties also reduces the risk of failures, which could compromise safety systems and cause costly equipment repairs or replacements.

-

You also want to think about your professional reputation. Using the right cable ties for the job shows professionalism and attention to detail. Customers are increasingly aware of the value of high-quality materials, so using UV stabilised cable ties, where appropriate, will enhance your reputation for great quality workmanship.

In short, if your job requires UV or heat resistance, then yes — it’s worth it.

Choosing the Right Supplier

Here’s what to look for:

-

Genuine UV-rated ties, ideally with UL certification

-

Consistent stock, especially if you're ordering in volume

-

Decent bulk pricing, especially for big installs

-

Real support - someone who knows cable ties and can guide you

Future of UV Cable Ties

The industry is moving fast, and there are some exciting advancements on the horizon, including:

-

Longer-life UV compounds

-

More recyclable and eco-friendly materials

-

Smart ties that detect strain or wear (still in early development)

Conclusion

UV Stabilised cable ties are an essential tool for professional cable management, especially in outdoor or UV-exposed environments. Their enhanced resistance to UV degradation and extreme temperatures, along with their safety compliance, make them a must-have for trade professionals who demand a reliable and long-lasting cable tie.

No matter whether you’re an electrician securing cable runs outdoors, a telecommunication engineer installing infrastructure, or an industrial maintenance professional managing complex systems, quality UV and heat resistant cable ties will save time and money in maintenance costs, as well as improve safety and increase your professional reputation.

The key to success lies in proper product selection, correct installation and buying from a reputable supplier who can provide both technical support and a high quality product. Understanding the science behind UV degradation and choosing the right product for the job allows trade professionals to ensure their installations remain secure and functional for years to come.

For your next outdoor project, consider the long-term benefits of UV stabilised cable ties. While the upfront costs may be higher than standard cable ties, the increased lifespan, reduced maintenance time and improved reliability make them the smart choice for professional application.

Whether you need a few ties for a small project or plan a large-scale installation requiring thousands of ties, quality UV stabilised cable ties are a long-term investment in the success of your work.

For bulk orders and project quotes on UV stabilised cable ties, contact our team who can provide competitive pricing and technical guidance tailored to your requirements.

Frequentky Asked Questions:

1. What are UV stabilised cable ties?

UV stabilised cable ties are nylon cable ties specially formulated with additives (like carbon black) to resist degradation caused by prolonged exposure to sunlight and ultraviolet (UV) radiation.

2. How long do UV stabilised cable ties last outdoors?

When properly installed, UV stabilised cable ties can last 5 to 10 years in outdoor conditions, depending on climate, UV intensity, and application. This makes them ideal for long-term outdoor use.

3. Are UV stabilised cable ties completely UV-proof?

No cable tie is 100% UV-proof, but UV stabilised ties are significantly more resistant than standard nylon ties and can withstand years of sun exposure without becoming brittle or cracking.

4. Can I use UV stabilised ties indoors as well?

Yes, UV stabilised ties can be used indoors. They offer the same mechanical strength and durability as standard ties, with the added benefit of UV resistance if installed near windows, skylights, or outdoor entry points.

5. What colour are UV stabilised cable ties?

Most UV stabilised cable ties are black, as black pigment (carbon black) is the most effective and economical UV stabiliser. Avoid using natural/white ties outdoors unless specifically UV-rated.

6. Are UV stabilised cable ties heat resistant too?

Yes, many UV stabilised ties are also heat-stabilised, operating safely between -40°C to +85°C (or higher depending on the spec). Always check the temperature rating for your specific product.

7. What sizes are available for UV stabilised ties?

They are typically available in a range of sizes from 100mm up to 1030mm long and widths from 2.5mm up to 12.7mm. This provides options for both small cable bundles and heavy-duty applications.

8. Are UV cable ties reusable?

No, standard UV stabilised cable ties are single-use and self-locking. If you need a reusable option, look for UV-resistant releasable cable ties.

9. Can UV stabilised ties be used in marine or coastal environments?

They perform better than standard ties, but for harsh saltwater or corrosive environments, stainless steel cable ties are more suitable due to their resistance to both UV and corrosion.

10. Do UV stabilised cable ties meet any industry standards?

Yes, many UV stabilised cable ties conform to standards such as UL94V-2 (flammability rating) and are RoHS compliant. Check the product specifications for individual certifications.